Jf-a Blender Boiler for Face Cream Vacuum Mixing Equipment Homogenizing Emulsifier

Basic Info

| Model NO. | JF-A |

| Certification | CE, RoHS |

| Application Area | Daily Chemical |

| Layout Type | Verticle |

| Mixing Drum Shape | Frame Scraper |

| Additional Capabilities | Milling |

| Operating type | Continuous Operating |

| Condition | New |

| Machine Material | SUS304&SUS316L |

| Control | Button/ Touch Screen |

| Heating Method | Steam/Electricity |

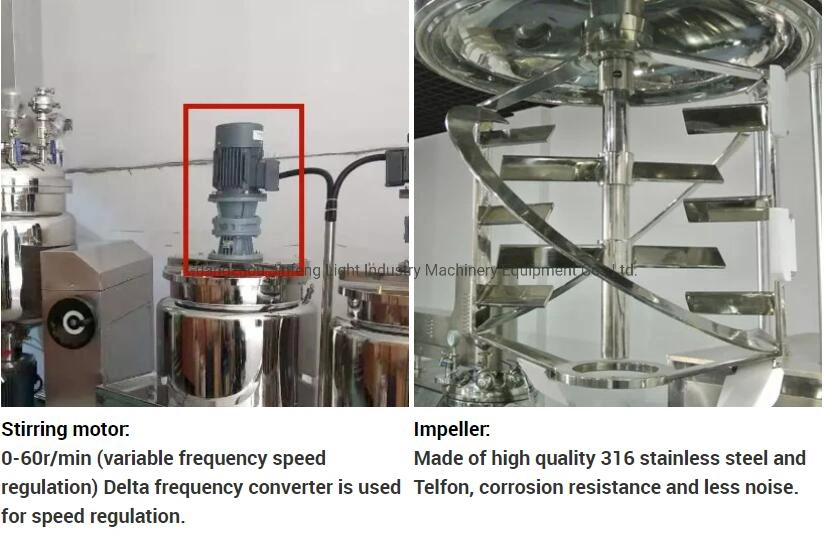

| Range of Spindle Speed | 0-60 r.p.m |

| Thickness | 2mm, 3mm, 4mm, 5mm, 6mm, 8mm etc. (Design Accordin |

| Jacket | Single Layer, Double Jacket, Three-Layer |

| Shape | Cylinder or Cone, Conical /Flat/Elliptical Bottom |

| Transport Package | Plywood Case Packing Suitable for Sea,Air Shipping |

| Specification | 50-5000L(customized is accepted) |

| Trademark | JINFENG |

| Origin | China |

| HS Code | 8474900000 |

| Production Capacity | 50-5000L(Customized Is Accepted) |

Product Description

| JF-A blender boiler for face cream vacuum mixing equipment homogenizing emulsifier |

Product Description

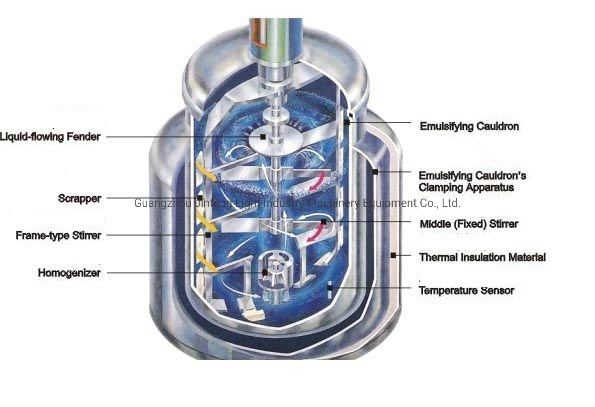

Vacuum Emulsifying Mixer

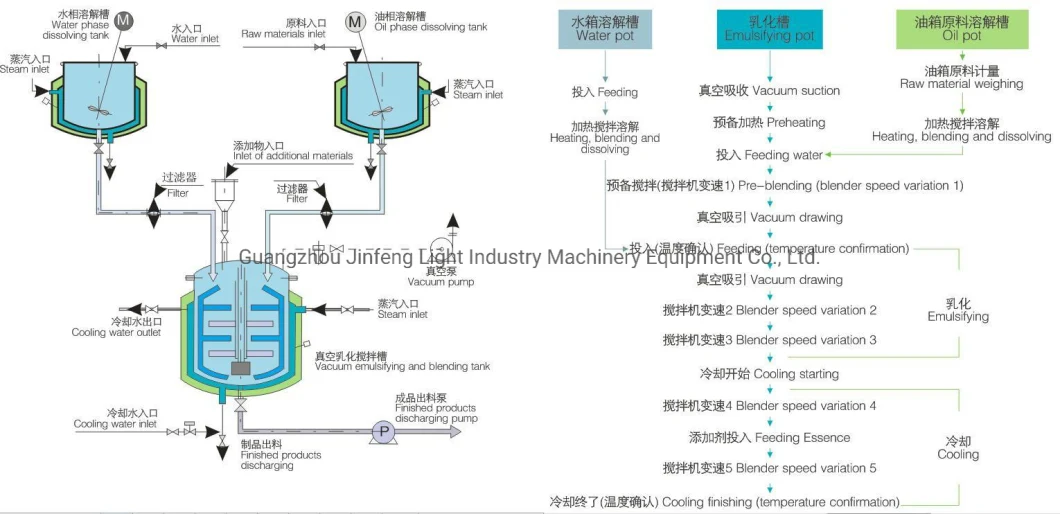

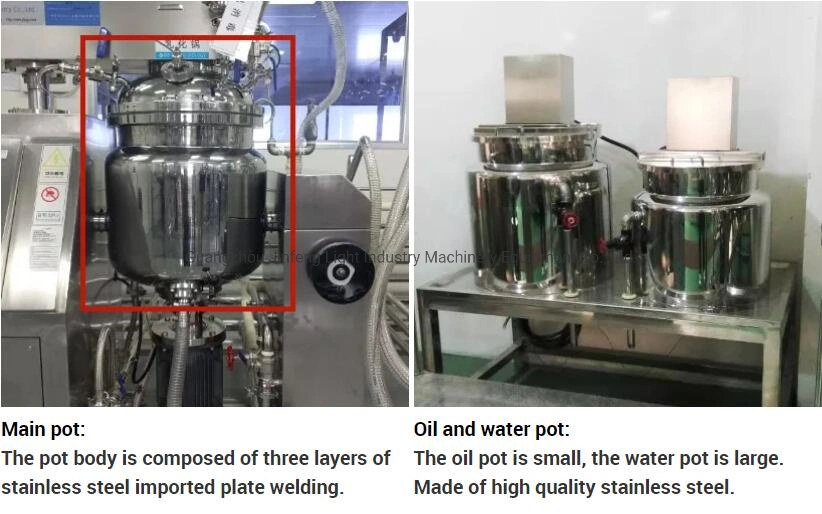

Vacuum homogeneous emulsifying machine is a set of mixing, dispersion, emulsification and homogenization, powder absorbing functions in one integrated system, a control system, but also with the peripheral oil, water tanks, the use of vacuum, heating / cooling system. Is a special equipment for producing medicinal ointment, cream, lotion and other high-grade.Definition of vacuum homogenizing emulsifierIt means that when the materials are under the vacuum condition, it make use of the high shear emulsifier to distribute one or several phases to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stator and rotor by strong energy of motion produced by the mechanical effect. By the operation of hydraulic shearing, centrifugal extruding, impacting, breaking, and turbulence for over 100 thousand times per minute, the materials will be dispersed and emulsified instantly and evenly. After reciprocating circulation and high frequency, the fine finished products of stable and high quality without bubbles will be achieved.Performances and Features1/ The Vacuum emulsifiers produced by our company include many varieties. The homogenizing systems include upper homogenization, lower homogenization, internal and external circulating homogenization. The mixing systems include single-way mixing, double-way mixing and helical ribbon mixing. The lifting systems include single-cylinder lifting and double-cylinder lifting. Various high quality products can be customized according to customer's requirements.2/ The triple mixing adopts the imported frequency converter for speed adjustment, which can meet different technological demands.3/ The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect. The maximum emulsifying rotation speed van reach 4,200 RPM and the highest shearing fineness can reach 0.2~5μm.4/ The vacuum degassing can make the materials meet the requirements of being aseptic. The vacuum materials sucking is adopted, and especially for the powder material, vacuum sucking can avoid dust.5/ The emulsifying pot lid can adopt lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge.6/ The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP requirements.7/ According to technological requirements, the tank body can heat or cool the materials. The heating modes mainly include steam heating or electric heating.8/ To ensure the control of the whole machine is more stable, the electric appliances adopt imported configurations, so as to fully meet the international standards.Main composition The vacuum emulsifying mixer is mainly composed of water pot, oil pot, emulsifying pot, vacuum system, electric control system (PLC is optional), operation platform, etc.Usage and application fieldThe product is mainly applied in such industries as daily chemical care products, bio pharmaceutical industry, food industry, paint and ink, petrochemical industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electrics and electronics, fine chemical industry, etc. The emulsifying effect is more prominent for material of high base viscosity ad high solid content.

Product Parameters

| Model | Effective capacity(L) | Emulsifier | Agitator | Machine size(mm) | Total power(KW) | |||||

| KW | R/min | KW | R/min | L | W | H | Electric heat | Steam heat | ||

| JF-B-100 | 100 | 2.8-4 | 1440/2880 | 1.5 | 0-63 | 2750 | 2700 | 2250 | 13 | 32 |

| JF-B-200 | 200 | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3100 | 3000 | 2500 | 15 | 45 |

| JF-B-300 | 300 | 6.5-8 | 1440/2880 | 2.2 | 0-63 | 3500 | 3350 | 2650 | 18 | 49 |

| JF-B-500 | 500 | 6.5-8 | 1440/2880 | 4 | 0-63 | 3850 | 3600 | 2750 | 22 | 61 |

| JF-B-1000 | 1000 | 9-11 | 1440/2880 | 5.5 | 0-63 | 4200 | 3850 | 3300 | 28 | 88 |

| JF-B-2000 | 2000 | 11-14 | 1440/2880 | 5.5 | 0-63 | 4500 | 4050 | 3800 | 34 | -- |

| JF-B-3000 | 3000 | 15-18 | 1440/2880 | 7.5 | 0-63 | 4800 | 4300 | 4100 | 40 | -- |

Note : In case of nonconformity of the data in the form due to technical improvement or customization , the real object shall prevail.

Detailed Photos

Packaging & Shipping

We will packs all of the machine and parts in the firm case that suitable for shipping.

Company Profile

Guangzhou Jinfeng Light Industry Machinery is a manufacturer that specializes in cosmetic, pharmaceutical, chemical and dairy product equipment. We undertake equipment design, manufacture, installation, maintenance, technical improvement support, technical consultancy and other services. The main products are vacuum homogeneous emulsifying machines, RO water treatment machines, filling machine, SUS storage tank and so on.JINFENG company have experienced professional design team, so we can provide our clients with comprehensive solutions that automatical series products constantly. The key elements of JINFENG series products adopt world-class brand products, and our products are well-known in good design, high performance, high efficiency, high precision and flexible operation.JINFENG company aims to build high quality, high efficiency, high performance equipment, stick to Science-First, People-oriented principles. We have the first-class after-sale service team and gain the customer's recognition.JINFENG company has confidence in professional team and high-quality products. We always cooperate with famous enterprises both at home and abroad. Your identity is our glory, your satisfaction is our motivation, we will pursue excellent quality, sincere service as in the past, and always guide the industry trend!FAQ

1. About Delivery termQ: What's the delivery term for doing business with you?

A: EXW/FOB/CIF/DDU… it depends on preference of clients. 2. About Lead timeQ: What's the leading time after placing order?

A: After getting your confirmation, mixing tank about 25 days, pump 15 days, colloid mill 10 days. However, it depends on production schedule is in slack or peak season, and the complication of machines. 3. About Payment timeQ: What's the payment term?

A: T/T 40% as down payment, 60% balance payment before delivery.4. About QualityQ: How do you control your quality?

A: All machines before delivery will be tested and send video for customer, if no problem then arrange balance payment. Meanwhile,CE is available for customers' needs.5. About PackingQ: How do you pack the machines?

A: Standard export wooden case, to avoid damage during delivery.6. About CustomizedQ: Can you produce according to the samples?

A: Yes,we can produce by your samples or technical drawings.